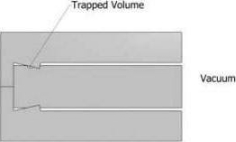

A virtual leak is a pocket of gas physically trapped within the weld with only a small, very low conductance, path from which to evacuate.

The trapped volume of gas within a vacuum chamber weld cannot be easily pumped out due to restrictions in the path. A cracked or imperfect weld is a common example.

Common examples of virtual leaks caused by poor design are:

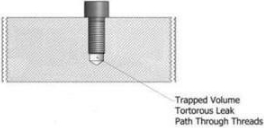

Trapped volumes caused by un-vented or poorly vented blind tapped holes within the vacuum volume.

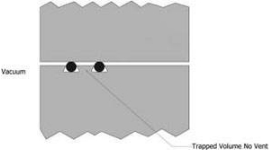

Trapped volumes caused by unvented double o-ring seal designs.

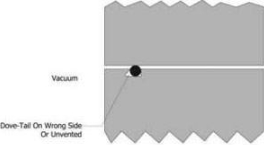

Trapped volumes caused by unvented single or double dovetail o-ring groove designs.

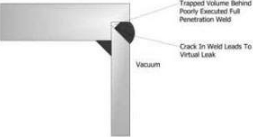

Trapped volume caused by incorrect weld design.

Common examples of virtual leaks caused by workmanship are:

Trapped volumes caused by poor weld fit up of full penetration welds and lack of penetration.

Trapped volumes caused by cracks in interior welds of braze joints.

Trapped volumes caused by uneven torquing of conflat flanges.

Virtual leaks are easily avoided if good vacuum practice is followed in the design and fabrication of your chamber. Future articles will discuss these practices.

This gas load is called a “virtual leak”.

To obtain a vacuum sealed joint, only one welding run has to be done on the inside(vacuum side). Structural runs have to be done outside with short skip runs that cover 30-45% of the joint.